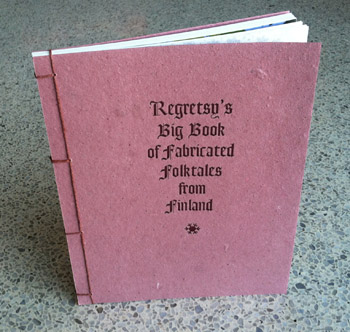

Regretsy’s Big Book of Fabricated Folktales from Finland

|

We were very pleased when we learned that April Winchell, creator of the popular website Regretsy, was writing a book to fund a Kickstarter grant. Since books are our thing, we offered to make a limited edition to help support her cause. |

The fiber for the cover paper came from two sources:

April Winchel's caftan (left) and Gabe Nelson's futon (right) provide the fiber used to make the covers for the Regretsy book.

|

It felt a bit wrong to cut up April’s caftan but we did our best to use only the back. Paper is made out of cellulose fibers. April’s caftan is definitely not made of cellulose so we had to use it sparingly or it would interrupt the hydrogen bond and make floppy paper. We can’t have floppy paper. |

| The futon fiber and caftan are processed into pulp using a hollander beater. We added the pigments at the end of the beating cycle. Several colors were combined to achieve the final color. |  |

A mould and deckle (right) are used to form the sheets of paper.

We formed the sheets one at a time using a mould and deckle and transferred them onto pieces of pellon. The process of transferring the paper off the mould is called ‘couching’ (pronounced cooch-ing). Another pellon is placed on top of the newly formed sheet and the next one is couched on top of that. The stack of formed sheets, called a post, is put in a hydraulic press to remove the water. The sheets are dried and then cut down to size for printing.

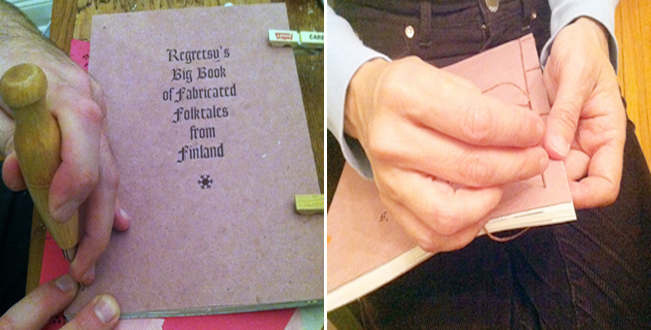

Goudy text (left) and a custom magnesium die (right) were used to print the covers.

We set the type by hand, placing each letter, one by one, into the form. We had a magnesium die made using artwork designed by John Foley (aka: Bronc Drywall).

Pam printing the front covers on a C&P.

Our friends at Playland Press let us use their treadle powered Chadlier & Price printing press to print the covers.

We used a hand-spun, hand-dyed thread to bind the books:

Pam spinning hemp singles on her spinning wheel (left) and the finished yarn (right).

Before we dyed the yarn we had to soak it in a mordant, a substance used to help the dye adhere to the fiber. The mordanting process was very involved and required an interesting step: a soak in sheep dung.

Binding thread simmering in a sheep dung fixing solution.

The excess mordant needs to be freed from the fiber otherwise the dye will simply bind to the mordant and wash away. This is where the sheep dung comes in. Dung from sheep and cattle contains sodium and calcium phosphates and was used for centuries for this purpose. Oh sure, we could use powdered chalk instead but why would we when we can use actual dung?

Dried madder root. |

We dyed the spun thread with natural madder root. This is also a rather involved process and took several days and repeated dye baths. |

| Wala! The finished thread waxed with beeswax from Pam’s San Francisco beehive. |  |

Pam and Drew bind the books.

Drew punched the holes for the binding using an awl and Pam sewed all the books.

Posted by BANDmade Books on December 29th, 2011facebook